Building materials

In the construction industry, safe, high-quality, robust and reliable cleaning systems are in demand. The success of MOOG Cleaning Systems is based on efficient high-pressure cleaning with cold/hot water and repetitively high results through programmed jet guidance - without the use of chemicals.

Application areas

-

Concrete mixers/concrete plants

Automatic internal cleaning.

User benefits

-

Efficiency

High-pressure cleaning with cold/hot water. Reproducible results thanks to programmed jet guidance.

High-pressure cleaning with cold/hot water. Reproducible results thanks to programmed jet guidance.

-

Conservation of resources

Sustainability thanks to high water and energy savings, no or minimal use of chemicals.

Sustainability thanks to high water and energy savings, no or minimal use of chemicals.

-

Reliability

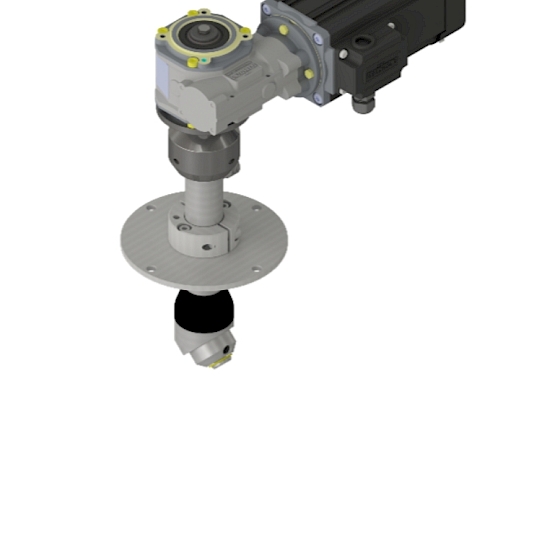

High-quality materials, robust design, precision manufacturing, operational reliability (guaranteed service and support) and easy maintenance.

High-quality materials, robust design, precision manufacturing, operational reliability (guaranteed service and support) and easy maintenance.

-

No additional infrastructure effort

Despite high performance, no additional power supply at the tank due to optional water-hydraulic drive of the cleaning heads.

Despite high performance, no additional power supply at the tank due to optional water-hydraulic drive of the cleaning heads.

-

Economic efficiency

Savings in cleaning time, personnel costs, reduction in water consumption and other resources, long service life (value retention).

Savings in cleaning time, personnel costs, reduction in water consumption and other resources, long service life (value retention).